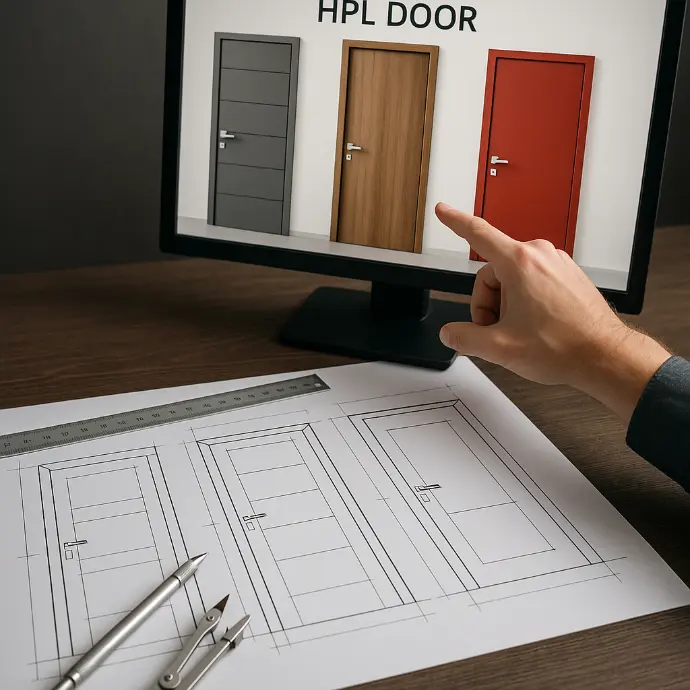

High-Pressure HPL Doors for Professional Projects

From Concept to Final Design at MEZ Door

At MEZ, we take care of every detail in manufacturing high-pressure HPL doors, from studying the project and selecting the right materials all the way to final finishing and packing, to deliver doors that combine durability, high quality, and elegant design.

1. Concept & Engineering Design

We begin by studying the required door type (interior, hotel, moisture-resistant) and defining its dimensions and function, then propose modern, wood-look or colored designs that match your project’s identity and needs.

2. HPL Materials & Core Selection

We use HPL sheets from approved suppliers with a suitable internal core such as Shipboard Hollow Core or Particle Board Semi Solid, in addition to moisture-resistant MDF and other support materials depending on the environment.

3. Precision Cutting & Assembly

Door components are cut using high-precision machines, then the frame and internal core are assembled and prepared to receive HPL layers on both faces to ensure a flat and stable surface.

4. Hot Pressing (Lamination)

The door passes through a special hot press that bonds the layers under high pressure and temperature, giving a surface that resists scratches and peeling and maintains excellent adhesion over time.

5. Finishing, Edges & Accessories

We finish the edges with solid wood and neat detailing, and prepare the openings for hinges, handles, and other accessories according to the drawings, so the door is fully ready for installation on site.

6. Inspection & Quality Control

Each door goes through dimensional checks, closing and alignment tests, and surface inspection to ensure it is free of defects, then it is carefully packed and prepared for delivery to the project site.

Ready to request a quotation for your HPL doors?

The Mezunt team helps you choose the best specifications for your doors, whether for hotel, commercial, or residential projects, with tailored solutions and well-planned execution time.

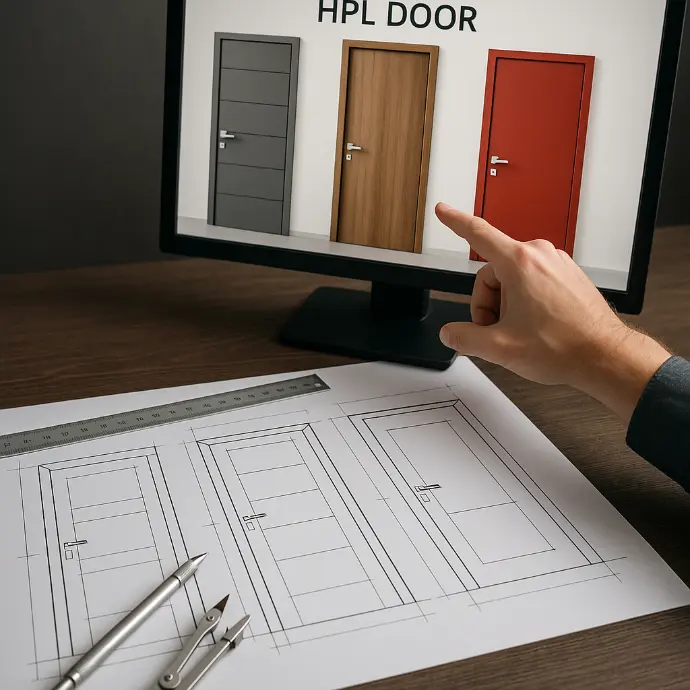

High-Pressure HPL Doors for Professional Projects

From Concept to Final Design at MEZ Door

At MEZ, we take care of every detail in manufacturing high-pressure HPL doors, from studying the project and selecting the right materials all the way to final finishing and packing, to deliver doors that combine durability, high quality, and elegant design.

1. Concept & Engineering Design

We begin by studying the required door type (interior, hotel, moisture-resistant) and defining its dimensions and function, then propose modern, wood-look or colored designs that match your project’s identity and needs.

2. HPL Materials & Core Selection

We use HPL sheets from approved suppliers with a suitable internal core such as Shipboard Hollow Core or Particle Board Semi Solid, in addition to moisture-resistant MDF and other support materials depending on the environment.

3. Precision Cutting & Assembly

Door components are cut using high-precision machines, then the frame and internal core are assembled and prepared to receive HPL layers on both faces to ensure a flat and stable surface.

4. Hot Pressing (Lamination)

The door passes through a special hot press that bonds the layers under high pressure and temperature, giving a surface that resists scratches and peeling and maintains excellent adhesion over time.

5. Finishing, Edges & Accessories

We finish the edges with solid wood and neat detailing, and prepare the openings for hinges, handles, and other accessories according to the drawings, so the door is fully ready for installation on site.

6. Inspection & Quality Control

Each door goes through dimensional checks, closing and alignment tests, and surface inspection to ensure it is free of defects, then it is carefully packed and prepared for delivery to the project site.

Ready to request a quotation for your HPL doors?

The Mezunt team helps you choose the best specifications for your doors, whether for hotel, commercial, or residential projects, with tailored solutions and well-planned execution time.

____________________________________________________________________________________________________________________________________________________________________________________________________________